Air conditioners are essential for comfort in hot and humid climates. They are devices that cool indoor spaces by removing heat and humidity from the air. Have you ever wondered how these seemingly magical devices work? They operate based on the principles of thermodynamics and the refrigeration cycle, a fascinating process that involves manipulating the properties of refrigerants to transfer heat from inside your home to the outside. Let’s delve into the inner workings of air conditioners and uncover the science behind their cooling power.

What Is an Air Conditioner?

An air conditioner is a device that lowers the temperature of indoor air by removing heat and moisture. Its primary purpose is to create a comfortable and healthy indoor environment by regulating temperature and humidity. But how does it achieve this? The basic principle behind air conditioning is the transfer of heat from the inside of a space to the outside, using a special fluid called a refrigerant that absorbs and releases heat as it changes state. Think of it like a heat shuttle, constantly moving heat energy from where you don’t want it to where it can be dissipated.

Types of Air Conditioners

There are several types of air conditioners available, each with its own set of advantages and disadvantages. Let’s explore some of the most common types:

Window Air Conditioners

Window air conditioners are self-contained units designed to be installed in a window opening. All their components, including the compressor, condenser, and evaporator, are housed in a single unit. They are typically suitable for cooling single rooms and are relatively inexpensive and easy to install. However, they can be noisy, block part of the window, and are generally less efficient than other types.

Portable Air Conditioners

Portable air conditioners are mobile units that can be moved from room to room. They have components similar to window units but include an exhaust hose to vent hot air outside. While they offer portability and don’t require permanent installation, they are generally less efficient, can be noisy, and still need a window or opening for the exhaust hose. It’s like having a cooling companion that follows you around, but with some strings attached.

Central Air Conditioning Systems

Central air conditioning systems are designed to cool an entire building using a network of ducts. They consist of an outdoor unit (containing the compressor and condenser), an indoor unit (housing the evaporator and air handler), and ductwork that distributes the cooled air. These systems offer efficient and quiet operation, with even cooling throughout the building. However, they are more expensive to install and require ductwork, making them a significant investment.

Ductless Mini-Split Systems

Ductless mini-split systems use individual indoor units connected to an outdoor unit via refrigerant lines. The outdoor unit houses the compressor and condenser, while one or more indoor units contain the evaporator and fan. These systems can cool single or multiple zones independently and are known for their efficiency, quiet operation, and flexible installation, as they don’t require ductwork. However, they come with a higher upfront cost than window or portable units and require professional installation.

Geothermal Cooling Systems

Geothermal cooling systems utilize the stable temperature of the earth to cool and heat buildings. They consist of a ground loop heat exchanger, a heat pump, and an indoor air handler. In cooling mode, heat is extracted from indoor air and transferred to the ground loop, where it is dissipated into the earth. These systems are highly efficient, environmentally friendly, and have a long lifespan. However, they come with a high installation cost and require sufficient land area for the ground loop. It’s like tapping into the earth’s natural coolness to keep your home comfortable.

Key Components of an Air Conditioner

Several key components work together to make the magic of air conditioning happen. Let’s take a closer look at each of these essential parts:

Refrigerant

The refrigerant is a fluid that absorbs and releases heat as it changes state between liquid and gas. It’s the lifeblood of the air conditioning system, constantly circulating and carrying heat. Refrigerants have specific properties, such as a low boiling point and high latent heat of vaporization, that make them ideal for this task.

There are various types of refrigerants, including R-22 (which is being phased out due to its ozone-depleting potential), R-410A (a common replacement for R-22), R-32 (with a lower global warming potential than R-410A), R-134a, and R-407C.

The choice of refrigerant significantly impacts the efficiency of the refrigeration cycle. Key properties include:

- Boiling Point: This determines the temperature at which the refrigerant evaporates and absorbs heat. Lower boiling points allow for lower operating pressures.

- Latent Heat of Vaporization: This is the amount of heat absorbed during evaporation. A higher latent heat means more heat is absorbed per unit mass of refrigerant, making the cooling process more efficient.

- Specific Heat Capacity: This property affects the amount of heat absorbed or released during sensible heating or cooling.

- Global Warming Potential (GWP): This measures how much heat a refrigerant traps in the atmosphere compared to carbon dioxide. Lower GWP refrigerants are more environmentally friendly.

- Ozone Depletion Potential (ODP): This measures a refrigerant’s ability to destroy stratospheric ozone. Zero ODP refrigerants are preferred for environmental reasons.

Compressor

The compressor is the heart of the AC system, responsible for compressing the refrigerant. It increases the pressure and temperature of the refrigerant gas, preparing it for the next stage of the cycle. At a molecular level, the compressor increases the kinetic energy of refrigerant molecules by reducing the volume they occupy. This increase in kinetic energy manifests as an increase in temperature and pressure. The compression process also increases the density of the refrigerant gas. There are several types of compressors:

Reciprocating Compressors

These use pistons to compress the refrigerant, similar to a car engine.

Scroll Compressors

These use two spiral-shaped scrolls to compress the refrigerant, offering quieter and more efficient operation.

Rotary Compressors

These use a rotating vane to compress the refrigerant, often found in smaller AC units.

Inverter-driven Compressors

These are becoming increasingly popular due to their variable-speed operation, which allows for improved efficiency and precise temperature control.

Condenser

The condenser is a heat exchanger where the hot, high-pressure refrigerant releases heat to the outside air. It’s like the radiator of your AC system. The condenser’s function is to condense the refrigerant from a gas back into a liquid. It consists of coils, fins, and a fan.

Here’s how it works: Hot refrigerant gas flows through the condenser coils. The fan blows outside air over the coils, absorbing heat from the refrigerant. As the refrigerant loses heat, it condenses into a liquid. This heat transfer process involves conduction (heat transfer from the refrigerant to the coils), convection (heat transfer from the coils to the air), and condensation (the refrigerant changing state, releasing latent heat).

Надихайтеся портфоліо датчиків руху Rayzeek.

Не знайшли те, що хотіли? Не хвилюйся. Завжди є альтернативні шляхи вирішення ваших проблем. Можливо, одне з наших портфоліо може допомогти.

Evaporator

The evaporator is another heat exchanger, but its role is to absorb heat from the indoor air. It’s where the refrigerant evaporates from a liquid into a gas, creating the cooling effect. The evaporator consists of coils, fins, and a fan (or blower).

The process is as follows: Liquid refrigerant flows through the evaporator coils. The fan blows indoor air over the coils, transferring heat to the refrigerant. As the refrigerant absorbs heat, it evaporates into a gas. This involves conduction (heat transfer from the air to the coils), convection (heat transfer from the air to the refrigerant), and evaporation (the refrigerant changing state, absorbing latent heat).

Expansion Valve

The expansion valve regulates the flow of refrigerant into the evaporator. It reduces the pressure and temperature of the refrigerant before it enters the evaporator, allowing it to absorb heat more effectively. There are two main types:

- Thermostatic Expansion Valve (TXV): This type regulates refrigerant flow based on evaporator temperature and pressure, providing precise control.

- Capillary Tube: This is a simpler, fixed-diameter tube that restricts refrigerant flow. It’s less expensive but also less precise than a TXV.

The expansion valve creates a pressure drop, causing the refrigerant to flash evaporate. This rapid expansion lowers the temperature of the refrigerant. The expansion valve maintains a specific pressure difference between the condenser and evaporator, ensuring the evaporator receives the correct amount of refrigerant to match the cooling load. Importantly, it prevents liquid refrigerant from entering the compressor, which can cause damage.

The Refrigeration Cycle Explained

The refrigeration cycle is the process by which air conditioners remove heat from indoor spaces. It consists of four main phases:

Compression Phase

The cycle begins with the compressor, which compresses low-pressure refrigerant gas into a high-pressure, high-temperature gas. This process requires work, increasing the internal energy of the refrigerant. The compressor essentially raises the refrigerant’s temperature above the outside air temperature, setting the stage for heat transfer.

Condensation Phase

The high-pressure, high-temperature refrigerant gas then flows to the condenser. Here, the condenser fan blows outside air over the condenser coils, removing heat from the refrigerant. As the refrigerant loses heat, it condenses into a high-pressure liquid, releasing latent heat in the process. This is where the heat from your home is expelled to the outside.

Expansion Phase

The high-pressure liquid refrigerant then passes through the expansion valve. This valve reduces the pressure of the refrigerant, causing it to partially evaporate into a low-pressure, low-temperature mixture of liquid and gas. This sudden drop in pressure and temperature is crucial for the next phase.

Evaporation Phase

The low-pressure, low-temperature refrigerant mixture enters the evaporator. The evaporator fan blows indoor air over the evaporator coils, transferring heat to the refrigerant. As the refrigerant absorbs heat, it fully evaporates into a low-pressure gas. The cooled air is then circulated back into the room, providing the desired cooling effect.

Delving into the Thermodynamic Principles of Refrigeration

The refrigeration cycle is a beautiful example of applied thermodynamics. Let’s break down the key principles at play:

- First Law of Thermodynamics: This law states that energy cannot be created or destroyed, only transferred or changed from one form to another. In the refrigeration cycle, the work input to the compressor is converted into heat, which is then transferred out of the system.

- Second Law of Thermodynamics: This law states that heat naturally flows from a hotter object to a colder object. The refrigeration cycle, however, uses work to move heat against this natural flow, from a colder space (inside) to a hotter space (outside). It’s like forcing water to flow uphill – it requires energy input.

- Entropy: This is a measure of disorder or randomness. The refrigeration cycle increases the entropy of the surroundings (outside air) while decreasing the entropy of the system (indoor air).

- Carnot Cycle: This is the most efficient theoretical thermodynamic cycle for refrigeration. Real-world refrigeration cycles deviate from the Carnot cycle due to irreversibilities, but it serves as an important benchmark for efficiency.

Pressure-Enthalpy Diagrams: Visualizing the Refrigeration Cycle

Pressure-enthalpy (P-h) diagrams are used to graphically represent the state of the refrigerant at different points in the refrigeration cycle. The diagram plots pressure on the y-axis and enthalpy (a measure of total heat content) on the x-axis.

Key points on the diagram include:

- Compressor inlet: Low pressure, low enthalpy

- Compressor outlet: High pressure, high enthalpy

- Condenser outlet: High pressure, medium enthalpy

- Expansion valve outlet: Low pressure, medium enthalpy

- Evaporator outlet: Low pressure, low enthalpy

The area enclosed by the cycle on the P-h diagram represents the work input to the compressor. The horizontal distance between the evaporator inlet and outlet represents the cooling capacity. These diagrams are essential tools for engineers designing and analyzing refrigeration systems.

The Importance of Superheat and Subcooling

Superheat and subcooling are two important concepts in refrigeration:

- Superheat: This is the amount of heat added to the refrigerant vapor after it has completely evaporated in the evaporator. It ensures that only vapor enters the compressor, preventing damage, and indicates the efficiency of the evaporation process. Typical superheat values range from 5-15°F (2.8-8.3°C).

- Subcooling: This is the amount of heat removed from the refrigerant liquid after it has completely condensed in the condenser. It ensures that only liquid enters the expansion valve, preventing flash gas and improving the efficiency of the expansion process. Typical subcooling values range from 10-20°F (5.6-11.1°C).

Understanding SEER Ratings

SEER, or Seasonal Energy Efficiency Ratio, measures the cooling efficiency of an air conditioner over an entire cooling season. It’s calculated by dividing the total cooling output (in BTUs) during a typical cooling season by the total electrical energy input (in watt-hours) during the same period. Higher SEER ratings indicate greater energy efficiency. Minimum SEER standards are set by regulatory bodies, such as the U.S. Department of Energy.

However, SEER has its limitations. It’s based on a standardized test procedure that may not accurately reflect real-world operating conditions. It also doesn’t account for variations in climate, usage patterns, and installation quality. Additionally, it primarily considers sensible cooling and may not fully capture the impact of dehumidification on energy consumption.

Understanding EER Ratings

EER, or Energy Efficiency Ratio, measures the cooling efficiency of an air conditioner at a specific outdoor temperature (95°F or 35°C). It’s calculated by dividing the cooling capacity (in BTUs per hour) by the power input (in watts) at that given temperature. Higher EER ratings indicate greater energy efficiency at higher temperatures. EER is a better indicator of performance in hot climates.

Like SEER, EER also has limitations. It represents performance at a single operating point and doesn’t capture efficiency variations across different temperatures. It may also not fully account for the impact of humidity on cooling performance and energy consumption.

Understanding BTU Ratings

BTU, or British Thermal Unit, is a measure of heat energy. In the context of air conditioners, it represents the cooling capacity – the amount of heat an air conditioner can remove from a space in one hour. Higher BTU ratings indicate greater cooling capacity.

Choosing the right BTU rating is crucial. It depends on factors such as room size, insulation, ceiling height, number of windows, and climate. Undersized units will struggle to cool the space effectively, while oversized units will cycle on and off too frequently, leading to poor dehumidification and reduced efficiency. It’s a delicate balance that requires careful consideration.

In-depth Exploration of Compressor Technology

Let’s dive deeper into the different types of compressors used in air conditioners:

Reciprocating Compressors: Mechanics and Efficiency

Reciprocating compressors use pistons driven by a crankshaft to compress the refrigerant gas. The operation involves a suction stroke (where the piston moves down, drawing in low-pressure gas), a compression stroke (where the piston moves up, compressing the gas), and a discharge stroke (where the high-pressure gas is discharged to the condenser).

Шукаєте енергозберігаючі рішення, що активуються рухом?

Звертайтеся до нас за комплексними PIR-датчиками руху, енергозберігаючими продуктами, що активуються рухом, вимикачами з датчиками руху та комерційними рішеннями для датчиків зайнятості/вакантності.

These compressors have moderate efficiency, which can be improved with multiple cylinders and capacity modulation. They are relatively simple in design and low in cost but can be noisy and prone to vibration. They also tend to have lower efficiency at part-load conditions.

Scroll Compressors: Design and Performance Advantages

Scroll compressors use two intermeshing scrolls – one stationary and one orbiting – to compress the refrigerant. Refrigerant gas is drawn into the outer portion of the scrolls. As the orbiting scroll moves, the gas is gradually compressed into smaller pockets towards the center. High-pressure gas is then discharged at the center of the scrolls.

These compressors offer high efficiency, especially at part-load conditions. They are known for their quiet operation, smooth and continuous compression, fewer moving parts, and high reliability. However, they come with a higher cost compared to reciprocating compressors.

Rotary Compressors: Applications and Operational Characteristics

Rotary compressors use a rolling piston or rotating vane inside a cylinder to compress the refrigerant. In the rolling piston type, a roller moves along the inside of the cylinder, compressing the gas in front of it. In the rotating vane type, vanes slide in and out of slots in a rotor, trapping and compressing the gas.

These compressors have moderate to high efficiency, depending on the design. They are compact, lightweight, and suitable for smaller applications. However, they can be less efficient than scroll compressors and have the potential for refrigerant leakage.

Inverter-Driven Compressors: Variable Speed Operation and Energy Savings

Inverter-driven compressors use a variable-frequency drive (inverter) to control the speed of the compressor motor. The inverter adjusts the frequency of the power supply to the motor, allowing the compressor to operate at different speeds. The compressor speed is matched to the cooling demand, providing precise temperature control.

These compressors offer very high efficiency, especially at part-load conditions. They provide significant energy savings, improved comfort, quieter operation, and a longer compressor lifespan. However, they come with a higher initial cost and more complex technology.

Advanced Heat Exchanger Designs for Enhanced Performance

Heat exchanger design plays a crucial role in the overall performance of an air conditioning system. Let’s explore some advanced designs:

Microchannel Heat Exchangers: Increased Surface Area and Heat Transfer

Microchannel heat exchangers use small, parallel channels instead of traditional round tubes for refrigerant flow. This design offers several advantages, including increased surface area for heat transfer, improved heat transfer coefficient, reduced refrigerant charge, and a compact size with lighter weight. They are commonly used in automotive air conditioning and are increasingly being adopted in residential and commercial systems.

Fin-and-Tube Heat Exchangers: Optimization of Fin Geometry and Spacing

Fin-and-tube heat exchangers consist of tubes that carry refrigerant and fins that enhance heat transfer to the air. Optimization of fin design is crucial for performance. Fin density (the number of fins per inch) is important – higher density increases surface area but can also increase air pressure drop. Fin shape also plays a role, with various shapes like louvered or corrugated fins enhancing air turbulence and heat transfer. Fin spacing is another factor, with optimal spacing balancing heat transfer and airflow resistance. Proper fin design can significantly improve heat transfer efficiency and reduce energy consumption.

Impact of Heat Exchanger Design on System Efficiency and Capacity

Heat exchanger design directly impacts the rate of heat transfer, which is their primary function. It also affects the pressure drop of both the refrigerant and the air, influencing compressor work and fan power. Additionally, the design influences the amount of refrigerant required in the system. Efficient heat exchangers contribute to higher cooling capacity, lower energy consumption, and improved SEER/EER ratings. They are a critical factor in overall system performance.

Maintaining Your Air Conditioner for Optimal Performance

Regular maintenance is essential to keep your air conditioner running efficiently and effectively. Here are some key maintenance tasks:

- Regularly clean or replace air filters: Dirty filters restrict airflow, reducing efficiency and cooling capacity.

- Clean the condenser and evaporator coils: Dirt and debris on the coils can impede heat transfer, making your system work harder.

- Перевірте рівень холодоагенту: Low refrigerant levels can indicate a leak and reduce system performance.

- Inspect and clean the condensate drain: A clogged drain can cause water damage and affect humidity control.

- Lubricate moving parts: Proper lubrication of fan motors and other moving parts ensures smooth operation and prevents wear.

- Schedule annual professional maintenance: A qualified technician can perform a comprehensive inspection, identify potential problems, and optimize system performance.

Proper maintenance can extend the lifespan of your air conditioner, improve energy efficiency, prevent costly repairs, ensure optimal cooling performance, and maintain good indoor air quality. It’s an investment that pays off in the long run.

Component sizing and matching are also crucial for optimal performance. The compressor capacity must be matched to the cooling load and the size of the condenser and evaporator. The condenser should be large enough to reject the heat absorbed by the evaporator plus the heat of compression. The evaporator should be appropriately sized to absorb the required amount of heat from the indoor space. The expansion valve type and size must be selected to provide the correct refrigerant flow rate and maintain optimal superheat. Finally, the fan or blower must provide sufficient airflow across the evaporator and condenser coils for effective heat transfer.

Mismatched components can lead to reduced cooling capacity, increased energy consumption, premature component failure, poor temperature and humidity control, and a shortened system lifespan. It’s like trying to run a marathon in shoes that are too small – you’re setting yourself up for failure.

Можливо, вас зацікавить

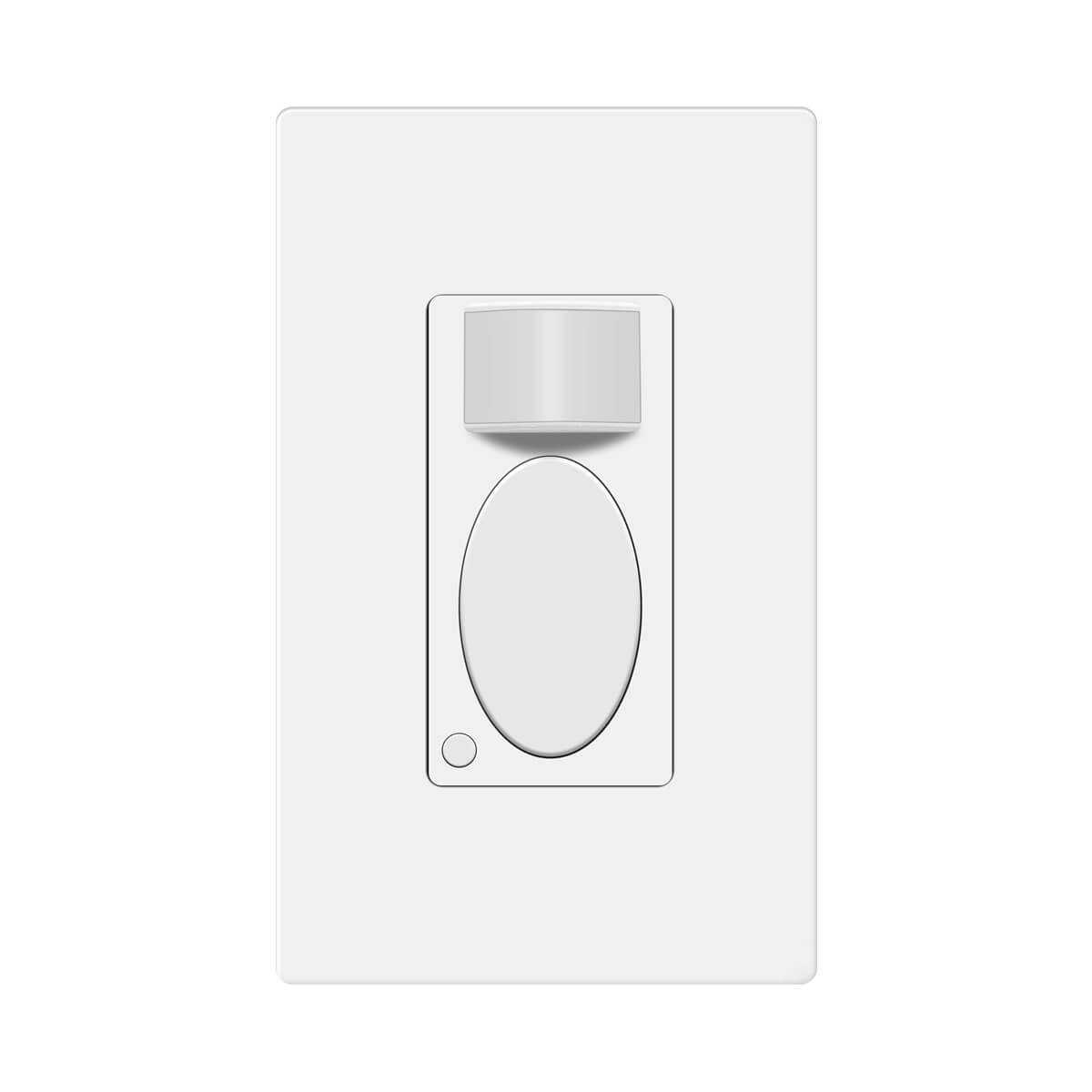

Beyond regular maintenance, you can further optimize your air conditioner’s performance and save significantly on energy costs with smart technology. For instance, have you ever considered that your AC might be running when no one’s home? A significant portion of energy is often wasted when air conditioners are left running in unoccupied rooms. This is where a smart solution like the Rayzeek RZ050 Air Conditioner Motion Sensor comes in.

The RZ050 is a simple yet effective device that automatically turns off your AC when a room is empty, preventing unnecessary energy consumption. It learns your AC remote’s “Power OFF” command and intelligently detects when a room is unoccupied, sending the signal to turn off the AC after a customizable delay. This not only saves you money on your energy bills but also extends the lifespan of your AC unit by reducing unnecessary wear and tear.

RZ050 Датчик руху кондиціонера

Automatically turn off your AC when you leave, saving energy and money.

- Save up to 50% on AC energy bills by automatically turning off the AC in empty rooms.

- Easy DIY installation with a wireless, battery-powered design – simply stick or screw it to the wall.

- Night mode ensures uninterrupted sleep by preventing the AC from turning off at night.

By incorporating the RZ050 into your AC maintenance routine, you’re not just ensuring your system runs smoothly; you’re actively taking a step towards a more energy-conscious and cost-effective approach to home cooling.