We kennen allemaal de schatting van 15-20 jaar, maar wat bepaalt nu echt de levensduur van een airconditioner? Het is een vraag die verder gaat dan een simpel getal en die zich verdiept in een complex samenspel van mechanische onderdelen, gebruikspatronen, omgevingsfactoren en onderhoudspraktijken.

Dit artikel is niet voor de toevallige huiseigenaar die op zoek is naar een snel antwoord. Het is voor de experts, de professionals en de veeleisende mensen die een dieper inzicht willen in de ingewikkelde factoren die bepalen hoe lang airconditioners meegaan.

We verkennen de technische nuances, de geavanceerde onderhoudsstrategieën en de opkomende technologieën die de toekomst van een lange levensduur van AC's vormgeven. Want als het om deze essentiële systemen gaat, is inzicht in hun levensduur cruciaal voor zowel comfort als financiële voorzichtigheid.

Hoe lang gaan airconditioners mee: factoren die de levensduur bepalen

De levensduur van een airconditioner is een veelzijdige vergelijking, beïnvloed door het type systeem, de onderdelen, de omgeving waarin het werkt en hoe het wordt gebruikt en onderhouden. Laten we deze factoren eens onder de loep nemen, te beginnen met de meest voorkomende typen airconditioners.

Centrale airconditioningsystemen: Verwachte levensduur

Centrale airconditioningsystemen zijn de werkpaarden van het wooncomfort en gaan meestal 15 tot 20 jaar mee. Dit bereik is echter een brede generalisatie. Factoren zoals tonnage, SEER-waarde en de kwaliteit van de eerste installatie spelen een belangrijke rol. Een systeem met de juiste afmetingen, afgestemd op de koelbehoeften van de woning, zal efficiënter werken en minder snel verslijten. De Seasonal Energy Efficiency Ratio (SEER) is een cruciale maatstaf, waarbij een hogere waarde duidt op een grotere efficiëntie en vaak ook op een langere levensduur omdat de onderdelen minder worden belast. Bovendien zorgt een onberispelijke installatie, inclusief goed ontworpen en afgedichte kanalen, voor een optimale luchtstroom en voorkomt het dat het systeem harder werkt dan nodig is. Zie het als een goed gestemd orkest - elk instrument moet in harmonie zijn voor optimale prestaties. Een slecht geïnstalleerd systeem daarentegen is als een symfonie met instrumenten die niet op elkaar zijn afgestemd, wat leidt tot een minder goede en mogelijk kortere levensduur.

Kanaalloze minisplitsystemen: Efficiëntie en duurzaamheid

Kanaalloze mini-splitsystemen hebben aan populariteit gewonnen vanwege hun energie-efficiëntie en gerichte koelingsmogelijkheden. Deze systemen hebben vaak een levensduur die vergelijkbaar is met of zelfs langer is dan die van centrale luchtsystemen, met veel systemen die meer dan 15-20 jaar meegaan. Een belangrijk voordeel is het gebruik van invertertechnologie, waardoor de compressor op variabele snelheden kan werken, wat het energieverbruik vermindert en slijtage minimaliseert. Bovendien elimineert de afwezigheid van leidingen potentiële problemen zoals lekken en energieverlies, wat bijdraagt aan een verbeterde efficiëntie en een lange levensduur. De zoneregeling die mini-splits bieden, zorgt voor koeling op maat in verschillende delen van het huis en voorkomt dat het systeem overbelast raakt om onbezette ruimten te koelen. Stelt u zich het verschil eens voor tussen een enkele gloeilamp die het hele huis verlicht en individuele lampen voor elke kamer - deze laatste zijn veel efficiënter en doelgerichter.

Raam- en draagbare units: Balanceren tussen kosten en levensduur

Raam- en mobiele airconditioners bieden een meer budgetvriendelijke koeloplossing, maar hun levensduur is meestal korter, gemiddeld ongeveer 8-10 jaar. Dit is deels te wijten aan hun ontwerp en gebruikspatronen. Vooral draagbare apparaten worden vaak van kamer naar kamer verplaatst of voor langere tijd opgeslagen, waardoor het risico op schade kan toenemen. Hoewel deze apparaten lagere initiële kosten hebben, is het essentieel om rekening te houden met hun kortere levensduur wanneer je de totale waarde overweegt. Ze dienen een doel, vooral voor kleinere ruimtes of als tijdelijke oplossing, maar ze zijn niet ontworpen voor de lange termijn zoals hun centrale of mini-split tegenhangers. Zie ze als de sprinters van de AC-wereld - ze zorgen voor een snelle koeling maar hebben niet het uithoudingsvermogen voor een marathon.

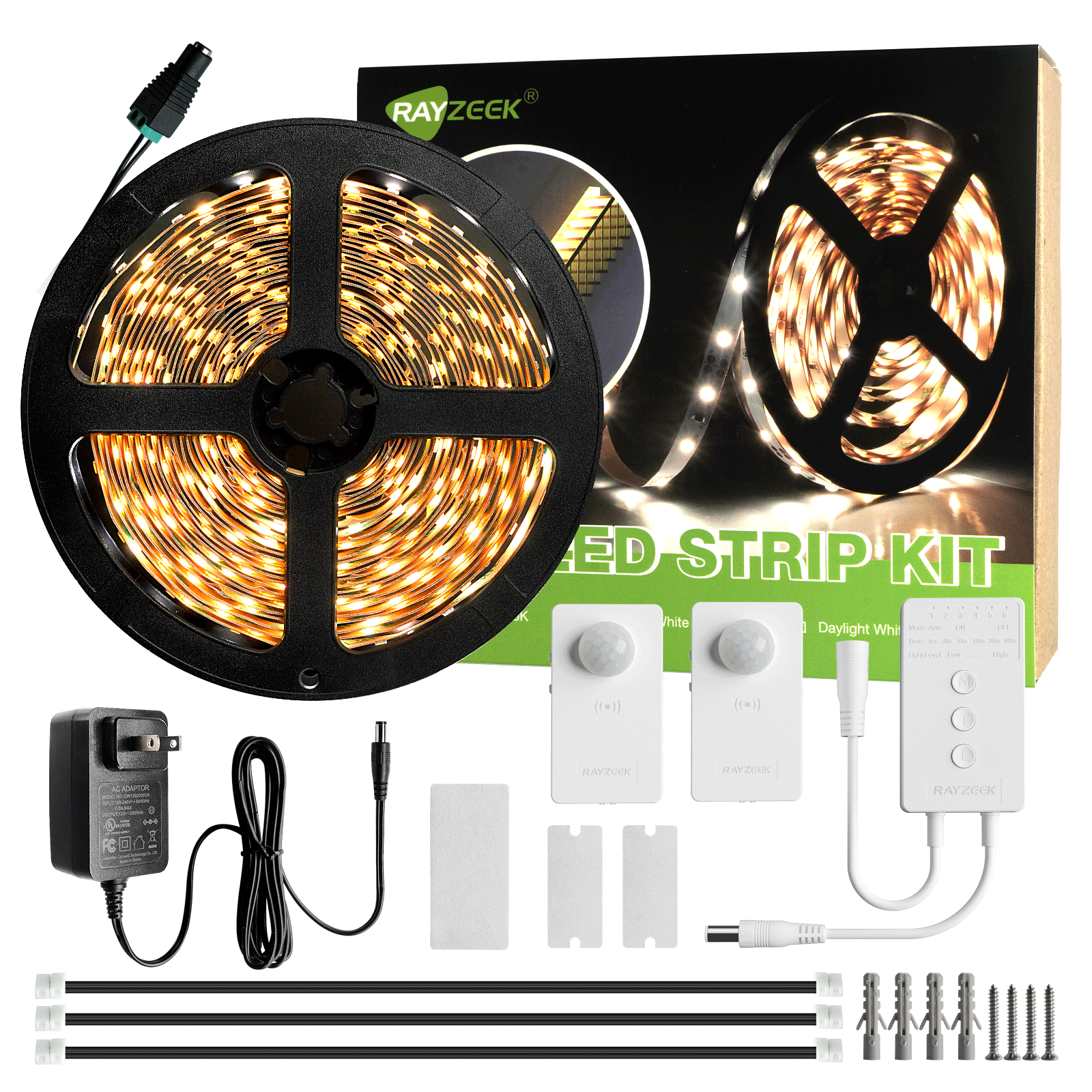

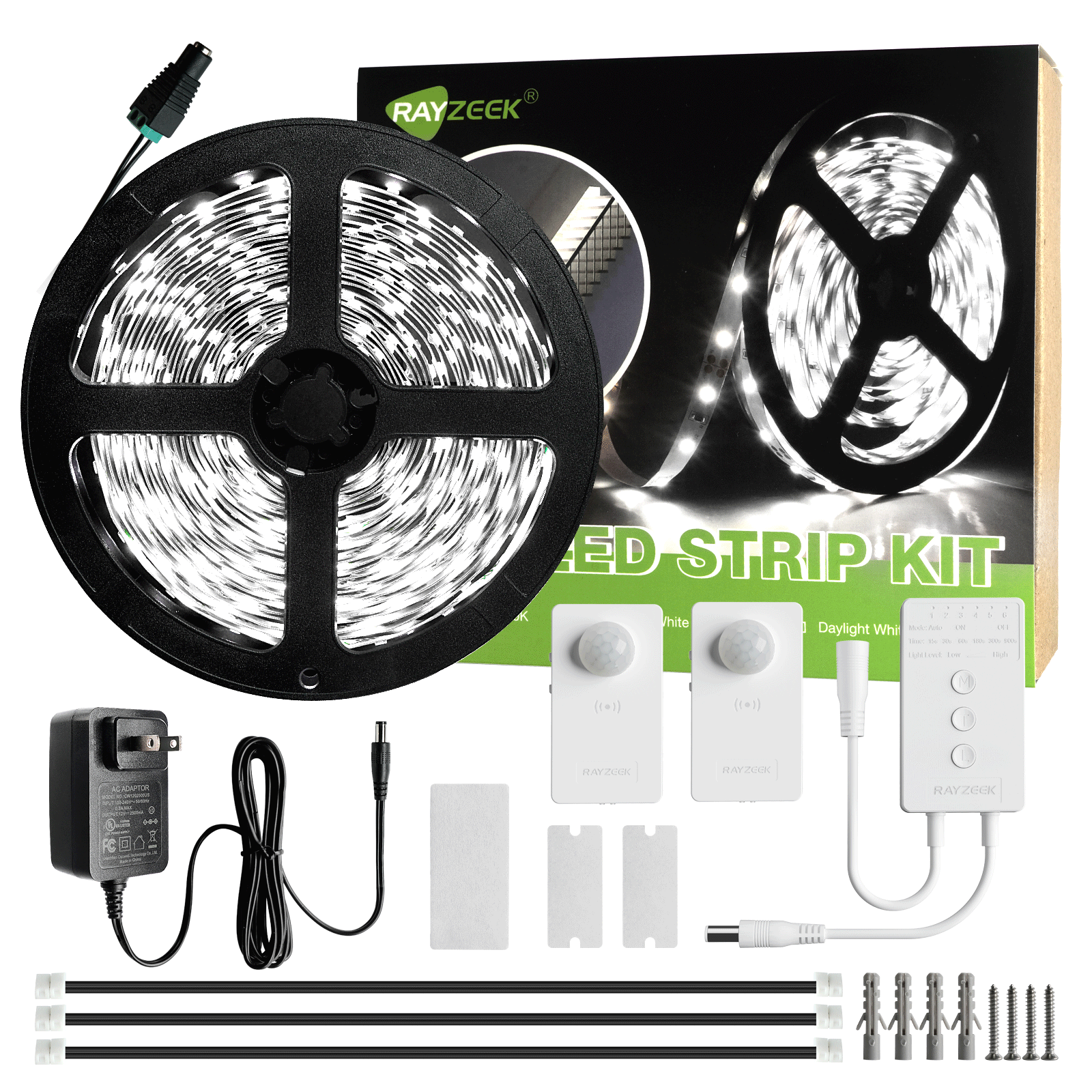

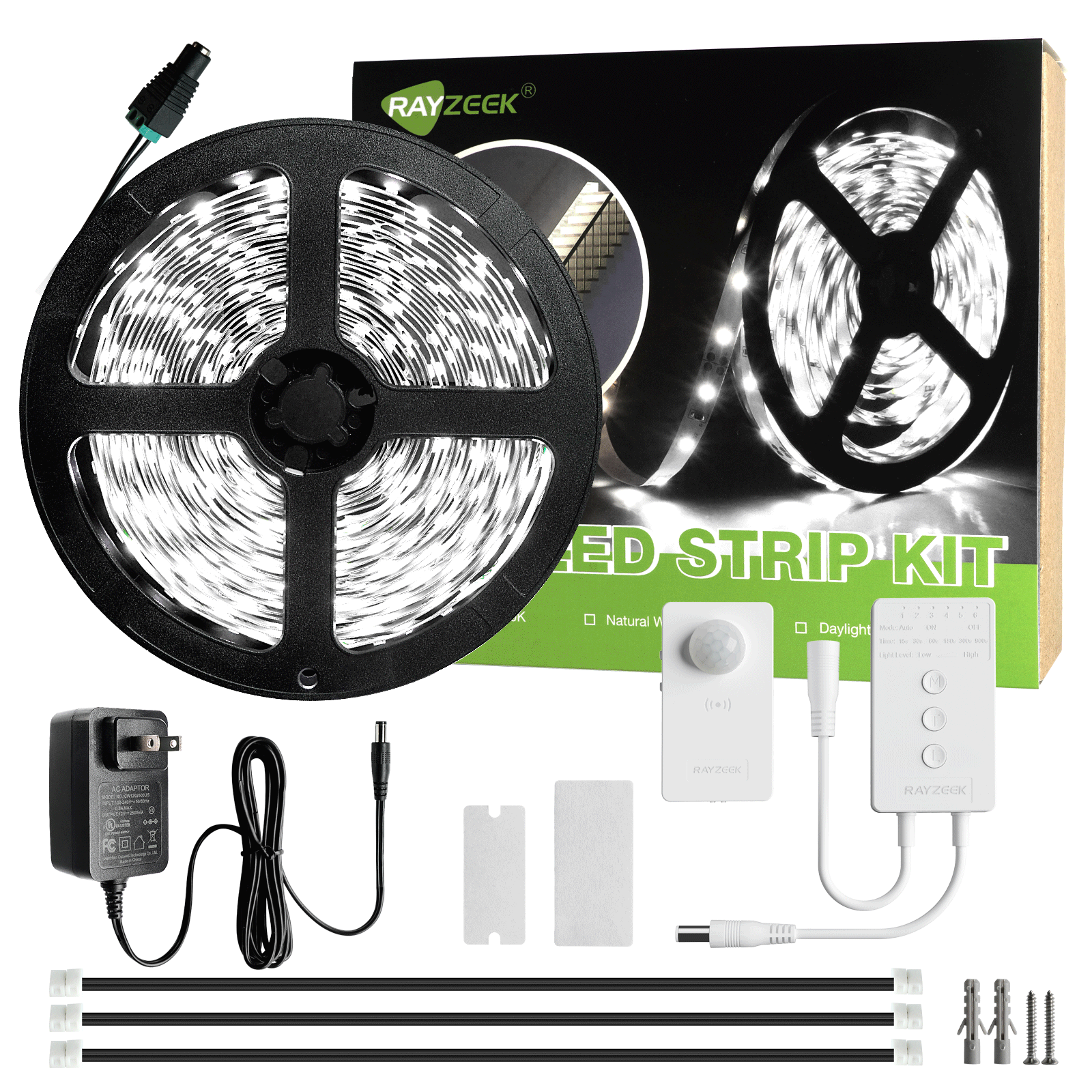

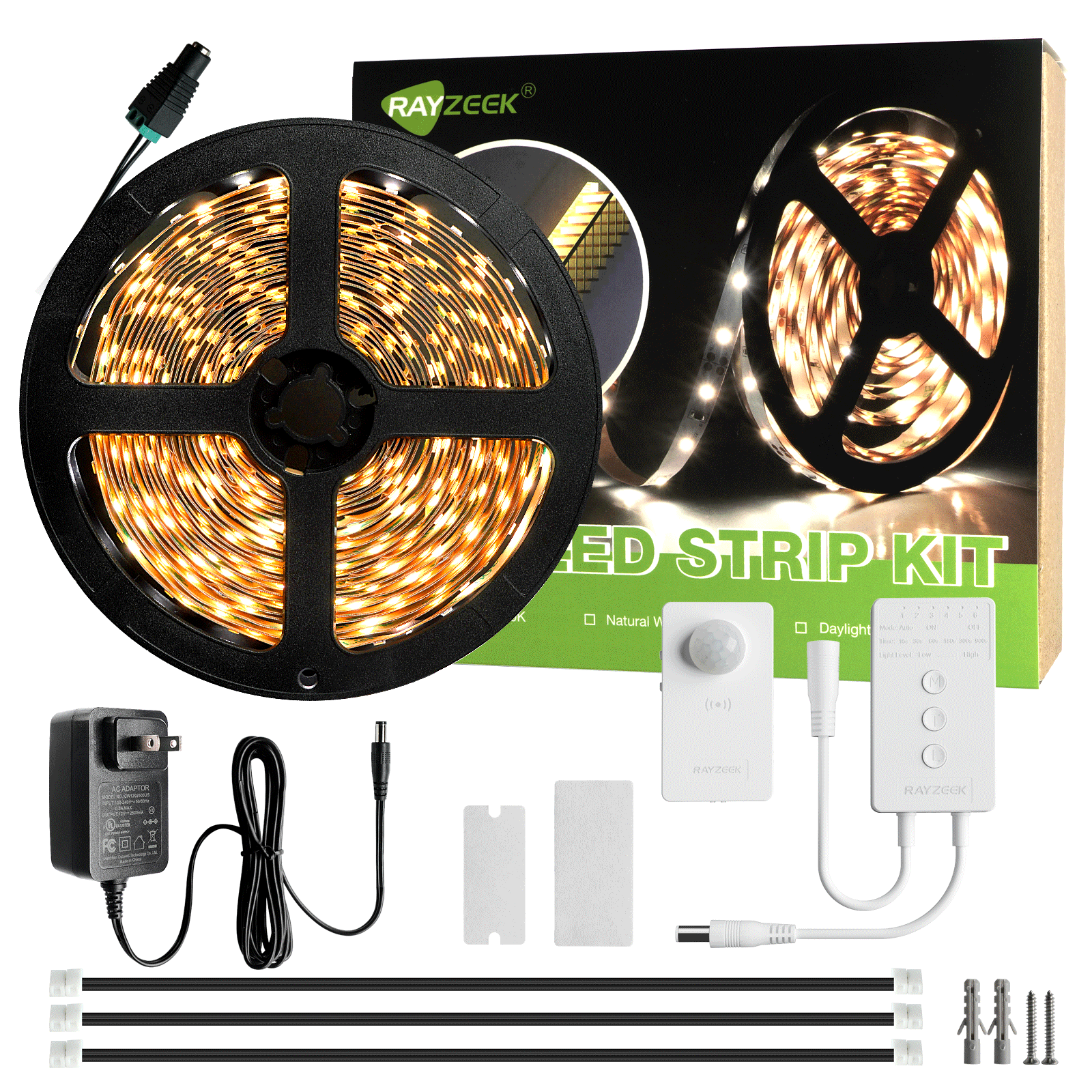

Laat u inspireren door Rayzeek Motion Sensor Portfolio's.

Vind je niet wat je zoekt? Maak je geen zorgen. Er zijn altijd alternatieve manieren om je problemen op te lossen. Misschien kan een van onze portfolio's helpen.

Onderdelen van airconditioners: Veelvoorkomende storingspunten

Om de levensduur van een airconditioner te begrijpen, is het van cruciaal belang om te weten hoe deze in elkaar zit. Elk onderdeel speelt een cruciale rol en het uitvallen van één onderdeel kan een grote impact hebben op het hele systeem.

Compressor: Het hart van het systeem

De compressor is het hart van het airconditioningsysteem, verantwoordelijk voor het circuleren van koelmiddel en het mogelijk maken van het warmtewisselingsproces. Net als het menselijk hart is het een vitaal orgaan dat onvermoeibaar werkt om alles soepel te laten verlopen. Compressoren, of het nu zuigercompressoren, scrollcompressoren of roterende compressoren zijn, gaan meestal tussen de 10 en 20 jaar mee, afhankelijk van gebruik en onderhoud. Ze zijn echter gevoelig voor verschillende problemen. Oververhitting, vaak veroorzaakt door een laag koelmiddelniveau of een beperkte luchtstroom, kan leiden tot voortijdige uitval. Elektrische storingen, zoals doorgebrande wikkelingen of defecte condensatoren, kunnen de compressor ook tot stilstand brengen. En zoals bij elk mechanisch onderdeel kan slijtage na verloop van tijd leiden tot een geleidelijke afname van de prestaties en uiteindelijk tot een defect. Regelmatig onderhoud, inclusief het garanderen van het juiste koelmiddelniveau en het direct oplossen van elektrische problemen, is cruciaal voor een maximale levensduur van de compressor.

Condensor- en verdamperspoelen: Warmte-uitwisseling en degradatie

De condensor- en verdamperspoelen zijn de onbezongen helden van het warmtewisselingsproces en zijn verantwoordelijk voor het opnemen en afgeven van warmte. Deze spoelen, meestal gemaakt van koper of aluminium, worden voortdurend blootgesteld aan de elementen en zijn gevoelig voor corrosie, vooral in kustomgevingen met een hoog zoutgehalte. Na verloop van tijd kunnen vuil, puin en verontreinigende stoffen zich ophopen op de spoelen, waardoor ze minder efficiënt worden en het systeem harder moet werken. Dit kan leiden tot een hoger energieverbruik, hogere bedrijfstemperaturen en uiteindelijk een kortere levensduur. Regelmatige reiniging van de batterijen is essentieel, en het gaat niet alleen om esthetiek. Het gaat erom een optimale warmteoverdracht te garanderen en te voorkomen dat het systeem overbelast raakt. Zie het als het reinigen van de radiator van een auto - het is cruciaal om oververhitting te voorkomen en de prestaties op peil te houden.

Koelmiddel: Soorten, lekken en prestaties

Koelmiddel is het levensbloed van een airconditioner, dat warmte absorbeert en afgeeft terwijl het door het systeem circuleert. Er bestaan verschillende soorten koelmiddelen, waarbij R-22 (Freon) geleidelijk wordt afgeschaft omdat het de ozonlaag kan aantasten en R-410A (Puron) de milieuvriendelijkere standaard wordt. Lekkage van koelmiddel is een veel voorkomend probleem dat de prestaties en levensduur van een airco aanzienlijk kan beïnvloeden. Een laag koelmiddelniveau dwingt de compressor harder te werken, wat leidt tot oververhitting en mogelijk defecten. Door lekkage kunnen ook vocht en verontreinigingen in het systeem terechtkomen, wat verdere schade kan veroorzaken. Het snel opsporen en repareren van lekken is cruciaal, en het gaat niet alleen om het behoud van koelprestaties. Het gaat om het beschermen van het milieu en het voorkomen van dure reparaties in de toekomst.

Elektrisch systeem: Bedrading, condensatoren en schakelaars

Het elektrische systeem levert de voeding en besturing die nodig zijn voor de werking van het AC-toestel. Componenten zoals condensatoren, contactgevers en bedrading zijn essentieel voor het starten van de compressor, het aansturen van de ventilatormotoren en het regelen van het hele systeem. Condensatoren, die elektrische energie opslaan en afgeven, hebben een beperkte levensduur en zijn gevoelig voor defecten, vooral in omgevingen met hoge temperaturen. Schakelaars, die fungeren als elektrische schakelaars, kunnen na verloop van tijd ook slijten door vonken en putjes. Defecte bedrading, losse verbindingen en stroompieken kunnen ook elektrische componenten beschadigen en leiden tot systeemstoringen. Regelmatige inspectie van het elektrische systeem door een gekwalificeerde technicus kan potentiële problemen opsporen voordat ze grote problemen veroorzaken.

Externe factoren: Invloed van milieu en gebruik op duurzaamheid

Naast de interne onderdelen spelen externe factoren een belangrijke rol bij het bepalen van de levensduur van een airconditioner. De omgeving waarin het apparaat werkt en hoe het wordt gebruikt, kunnen een grote invloed hebben op de levensduur.

Klimaat en corrosie: Strijd tegen de elementen

Het klimaat bepaalt in grote mate de levensduur van een airco. Toestellen in warme, vochtige klimaten, met name aan de kust, hebben voortdurend te maken met corrosie. De combinatie van hoge temperaturen, vocht en zoute lucht kan de degradatie van metalen componenten versnellen, vooral condenserspoelen. Extreme temperatuurschommelingen kunnen componenten ook belasten en leiden tot voortijdige uitval. In dergelijke omgevingen kan de keuze voor corrosiebestendige materialen en beschermende maatregelen, zoals het regelmatig spoelen van de buitenunit, helpen om de schadelijke effecten van de elementen te beperken.

Gebruikspatronen en thermostaatstrategieën: De juiste spot vinden

Hoe een airconditioner wordt gebruikt, kan de levensduur aanzienlijk beïnvloeden. Vaak in- en uitschakelen kan de compressor en andere onderdelen extra belasten. De airco constant op zeer lage temperaturen laten werken kan ook leiden tot verhoogde slijtage. Het is cruciaal om de juiste thermostaatinstellingen te vinden. Programmeerbare of slimme thermostaten kunnen helpen het gebruik te optimaliseren door de temperatuur automatisch aan te passen op basis van bezetting en tijdstip. Dit bespaart niet alleen energie, maar vermindert ook de belasting op het systeem, wat bijdraagt aan een langere levensduur. Het gaat erom een balans te vinden tussen comfort en efficiëntie, zodat de AC-unit slimmer werkt in plaats van harder.

Luchtkwaliteit: De stille moordenaar van airco-units

De luchtkwaliteit binnenshuis wordt vaak over het hoofd gezien, maar speelt een cruciale rol in de levensduur van een airco. Stof, pollen, huidschilfers van huisdieren en andere vervuilende stoffen kunnen zich ophopen op filters en spoelen, waardoor de luchtstroom wordt beperkt en de efficiëntie afneemt. Dit dwingt het systeem om harder te werken, waardoor het energieverbruik toeneemt en onderdelen mogelijk defect raken. Het regelmatig vervangen van luchtfilters is essentieel en het kiezen van het juiste filter is net zo belangrijk. Filters met een hogere MERV (Minimum Efficiency Reporting Value) waarde vangen meer deeltjes in de lucht op, maar kunnen de luchtstroom beperken als ze niet goed op het systeem zijn afgestemd. Het verbeteren van de algehele luchtkwaliteit binnenshuis door maatregelen zoals het gebruik van luchtreinigers en het zorgen voor een goede ventilatie kan ook bijdragen aan een gezondere AC-eenheid die langer meegaat.

Op zoek naar bewegingsgevoelige energiebesparende oplossingen?

Neem contact met ons op voor complete PIR-bewegingssensoren, bewegingsgeactiveerde energiebesparende producten, bewegingssensorschakelaars en commerciële Occupancy/Vacancy-oplossingen.

Geavanceerd onderhoud: Strategieën om de levensduur van de airconditioning te maximaliseren

Hoewel routineonderhoud zoals het vervangen van filters essentieel is, vereist het maximaliseren van de levensduur van een airco een meer proactieve en diepgaande aanpak. Geavanceerde onderhoudstechnieken kunnen problemen helpen voorkomen, de prestaties optimaliseren en de levensduur van het systeem verlengen.

Verder dan filtervervangingen: Dieptereiniging en systeemoptimalisatie

Dieptereiniging gaat verder dan alleen het vervangen van het luchtfilter. Het omvat het grondig reinigen van de condensor- en verdamperspiralen, het verwijderen van vuil, puin en tekenen van corrosie. Dit kan worden gedaan met speciale spoelreinigers en een zachte borstel of een waternevel onder lage druk. De condensafvoerleiding moet ook worden geïnspecteerd en gereinigd om verstoppingen te voorkomen, die kunnen leiden tot waterschade en systeemstoringen. De ventilatormotor en ventilatorbladen moeten worden geïnspecteerd en schoongemaakt om een goede luchtstroom te garanderen. Het smeren van bewegende delen, zoals de lagers van de ventilatormotor, kan ook wrijving en slijtage helpen verminderen. Deze taken kunnen het beste worden uitgevoerd door een gekwalificeerde HVAC-monteur die de expertise en het gereedschap heeft om de klus veilig en effectief te klaren.

Beheer van koelmiddelen: Lekdetectie en prestatietests

Koudemiddelbeheer is cruciaal voor het behouden van optimale prestaties en het voorkomen van schade aan de compressor. Geavanceerde lekdetectiemethoden, zoals het gebruik van elektronische lekdetectoren, kunnen zelfs kleine lekken opsporen die anders misschien onopgemerkt blijven. Regelmatige druktests kunnen het koudemiddelniveau en de systeemprestaties beoordelen en potentiële problemen identificeren voordat ze tot grote problemen leiden. Het is belangrijk om te weten dat het omgaan met koudemiddel een speciale opleiding en certificering vereist vanwege milieuregelgeving. Vertrouw altijd op een gekwalificeerde technicus voor alle werkzaamheden met betrekking tot koelmiddelen.

Diagnose elektrisch systeem: Mogelijke problemen identificeren

Regelmatige inspecties van het elektrische systeem kunnen onverwachte storingen helpen voorkomen en de levensduur van elektrische componenten verlengen. Met behulp van een multimeter kan een technicus condensatoren en schakelaars testen om er zeker van te zijn dat ze binnen de specificaties werken. Bedrading moet worden geïnspecteerd op tekenen van schade, zoals rafelen of verkleuring. Losse verbindingen moeten worden aangedraaid om kortsluiting te voorkomen. Met deze diagnoses kunnen potentiële problemen worden opgespoord voordat ze grote problemen veroorzaken, zodat je geen dure reparaties hoeft uit te voeren en je AC-systeem goed blijft werken.

De toekomst van AC-lang leven: Innovaties en opkomende technologieën

De HVAC-technologie is voortdurend in ontwikkeling, met nieuwe innovaties en opkomende technologieën die de efficiëntie, betrouwbaarheid en levensduur verbeteren.

Invertertechnologie en compressoren met variabele snelheid

Invertertechnologie heeft een revolutie teweeggebracht in de HVAC-industrie, waardoor compressoren op variabele snelheden kunnen werken in plaats van op volle capaciteit aan en uit te gaan. Deze werking met variabele snelheid verlaagt het energieverbruik aanzienlijk en minimaliseert de slijtage van de compressor. Door de snelheid aan te passen aan de koelvraag behouden inverter AC-units een consistentere temperatuur, werken ze stiller en ondervinden ze minder belasting van de componenten, wat bijdraagt aan een langere levensduur.

Slimme thermostaten en voorspellend onderhoud: De opkomst van intelligente HVAC

Slimme thermostaten worden steeds geavanceerder en maken gebruik van algoritmes voor machinaal leren om gebruikspatronen te leren en de werking van de AC te optimaliseren. Ze kunnen automatisch de temperatuur aanpassen op basis van bezetting, tijd van de dag en zelfs weersvoorspellingen, waardoor de energie-efficiëntie wordt gemaximaliseerd en het systeem minder wordt belast. Voorspellend onderhoud is een andere opwindende ontwikkeling, waarbij sensoren en gegevensanalyse worden gebruikt om de systeemprestaties te controleren en potentiële problemen op te sporen voordat ze zich voordoen. Door gegevens over temperatuur, luchtstroom, trillingen en andere parameters te analyseren, kunnen deze systemen huiseigenaren of technici waarschuwen voor mogelijke problemen, waardoor proactief onderhoud mogelijk wordt en kostbare storingen worden voorkomen.

Het concept van slimme HVAC gaat een stap verder en innovatieve oplossingen zoals de RZ050 airconditioner bewegingssensor zijn in opkomst om bestaande airconditioners uit te breiden met intelligente automatisering. De RZ050 voegt een op bezettingsgraad gebaseerde controlelaag toe aan je huidige airconditioner en zorgt ervoor dat deze alleen draait wanneer dat nodig is. Dit bespaart niet alleen energie, maar draagt ook bij aan een langere levensduur van je airco door onnodige slijtage te verminderen.

RZ050: De toekomst van AC-efficiëntie

Upgrade je AC met slimme aanwezigheidsdetectie.

- Integreert naadloos met de meeste split AC-units.

- De nachtmodus zorgt voor een ononderbroken slaap.

- Verlaagt de energierekening met wel 50%.

Door de AC automatisch uit te schakelen wanneer een kamer niet bezet is, is de RZ050 een voorbeeld van de principes van intelligente HVAC. Het is een eenvoudige maar krachtige manier om je bestaande systeem te upgraden, zodat het slimmer en efficiënter wordt zonder dat er een complete revisie nodig is.

De economische aspecten van de levensduur van airconditioning: Reparatie, vervanging en ROI

Inzicht in de economische aspecten van de levensduur van AC's is cruciaal om weloverwogen beslissingen te kunnen nemen over reparatie, vervanging en het maximaliseren van het rendement op investering (ROI).

Misschien bent u geïnteresseerd in

De ernst van reparaties beoordelen: Is het de moeite waard om te repareren?

Wanneer een airconditioner kapot gaat, rijst onvermijdelijk de vraag of hij moet worden gerepareerd of vervangen. Verschillende factoren moeten in overweging worden genomen, waaronder de leeftijd van de unit, de kosten van de reparatie, de frequentie van storingen en de algemene staat van het systeem. Als algemene regel geldt dat als de reparatiekosten meer bedragen dan 50% van de kosten van een nieuwe unit, vervanging vaak de voordeligste optie is. Ook als de unit het einde van zijn verwachte levensduur nadert en meerdere storingen heeft gehad, kan het tijd zijn om een upgrade te overwegen.

Terugverdientijden berekenen voor nieuwe hoogrendementunits

Investeren in een nieuwe, hoogefficiënte airco-eenheid kan op de lange termijn aanzienlijk besparen op de energierekening. Om de financiële haalbaarheid van een vervanging te bepalen, is het essentieel om de terugverdientijd te berekenen. Dit kan gedaan worden met een eenvoudige formule:

Terugverdientijd (jaren) = Kosten nieuwe eenheid / Jaarlijkse energiebesparing

Als een nieuwe unit bijvoorbeeld $5.000 kost en naar verwachting $500 per jaar aan energiekosten bespaart, is de terugverdientijd 10 jaar. Factoren zoals SEER-waarde, energiekosten in uw omgeving en uw typische gebruikspatronen moeten in overweging worden genomen bij het schatten van de energiebesparingen.

Prestaties, levensduur en duurzaamheid in evenwicht brengen

Bij het kiezen van een nieuwe airco is het belangrijk om niet alleen te kijken naar de prestaties en de levensduur, maar ook naar duurzaamheid. Door te kiezen voor een unit met een hoge SEER-waarde en een milieuvriendelijk koelmiddel kun je je ecologische voetafdruk verkleinen. Door te kiezen voor een duurzame unit die lang meegaat, minimaliseer je ook het afval en bespaar je hulpbronnen. Een verantwoorde afvoer van de oude unit is ook cruciaal, zodat koelmiddelen en andere materialen op de juiste manier worden verwerkt.

Conclusie: AC levensduur beheersen

Het beheersen van de levensduur van AC's gaat niet over het vinden van een magisch getal. Het gaat om het begrijpen van het ingewikkelde samenspel van factoren die de levensduur van deze complexe systemen beïnvloeden. Het gaat erom geavanceerde onderhoudspraktijken te omarmen, op de hoogte te blijven van nieuwe technologieën en weloverwogen beslissingen te nemen over reparatie en vervanging. Door technische kennis, praktische vaardigheden en een proactieve benadering te combineren, kunt u het lot van uw AC in eigen handen nemen en zorgen voor jarenlang betrouwbaar comfort terwijl u uw investering maximaliseert en de impact op het milieu minimaliseert. De reis naar het beheersen van de levensduur van een AC is een continu leerproces, maar wel een proces dat uiteindelijk leidt tot een comfortabelere, efficiëntere en duurzamere toekomst.