Energy savings – what does that term really mean? Simply put, it’s about reducing the amount of energy we use while still achieving the same level of output or service. And you’ve probably noticed that energy savings has become increasingly crucial in recent years. Why is that? Well, there are a couple of big reasons.

First, there’s the urgent need to tackle climate change by reducing greenhouse gas emissions. Burning fossil fuels (like coal, oil, and natural gas) to produce energy is a major source of these emissions. So, when we reduce our energy consumption, we directly reduce the amount of greenhouse gases released into the atmosphere.

The second major driver is the ever-increasing cost of energy. Whether you’re an individual or a business, rising energy costs can really hit your wallet. For households, it means higher expenses and less disposable income. For businesses, it translates to increased operational costs, which can impact profitability and their ability to compete.

Now, you might think that measuring energy savings is as simple as looking at your energy bills and seeing a lower number. But it’s actually a bit more complex than that! Accurately measuring energy savings is a scientific and engineering discipline that requires rigorous methods and careful analysis. Why can’t we just rely on those lower bills? Because lower energy bills could be due to a variety of factors – changes in the weather, whether you’re home or away, or even changes in production levels at a factory. To truly understand the impact of energy-saving measures, we need to isolate their effect.

Here’s something to think about: it’s estimated that readily available, cost-effective energy efficiency technologies could reduce global energy consumption by 20-30% or more! That’s a huge potential savings. But to unlock that potential, we need to accurately measure and verify our energy savings. Without accurate measurement, how can we know if these technologies are actually working as intended? And how can we justify further investments in energy efficiency?

So, how do we go about measuring energy savings? This article will give you a comprehensive overview of the process, covering all the key aspects. We’ll be diving into topics like Measurement and Verification (M&V) – which is a widely used methodology for quantifying energy savings – and how to establish a baseline, which serves as a crucial reference point. We’ll also explore the various calculation methods used to determine savings, discuss some common challenges you might encounter, and even touch on some advanced techniques for more complex situations.

What is Energy Savings Measurement?

So, what exactly is energy savings measurement? It’s the process of figuring out just how much we’ve reduced our energy consumption thanks to specific actions or interventions. It’s more than just noticing that your energy bills are a little lower. It’s about objectively determining the difference in energy use between a period before you made a change and a period after you made that change. This objective determination is super important because it allows us to really see how effective our energy efficiency efforts are. Without it, we can’t say for sure that changes in energy consumption are actually due to the actions we’ve taken. For instance, switching to LED lighting, upgrading your HVAC systems (that’s your heating, ventilation, and air conditioning), or improving your building’s insulation are all examples of energy-saving interventions. The measurement process tells us how much energy these changes actually save, giving us hard data on their effectiveness. Let’s say a factory uses 1000 kWh (kilowatt-hours) of electricity per day to produce a certain number of widgets. Then, they implement a new, more efficient process that reduces electricity consumption to 800 kWh per day for the same number of widgets. In that case, the energy savings are 200 kWh per day. By “the same number of widgets,” we mean that the production output stays constant. This is important because changes in production levels could affect energy consumption, regardless of any efficiency improvements.

The basic idea behind energy savings measurement is pretty straightforward: we compare energy use before and after we make a change. This means we need to establish a “baseline” – a snapshot of how much energy we were using before we implemented any energy-saving measures. Then, we measure energy consumption after the intervention. The difference between the baseline and what we consume after the change represents the energy savings. Think of it like weighing yourself before and after going on a diet to see how much weight you’ve lost. Your initial weight is the baseline, and the difference between your initial and final weights is the weight loss.

Now, here’s a critical point: accurate measurements are essential when assessing energy savings. Why? Because inaccurate measurements can lead us to draw the wrong conclusions about how well our energy-saving measures are working. This can throw off investment decisions, causing us to put money into measures that aren’t actually effective. Inaccurate data can also mess up policy development, leading to regulations and incentives that don’t achieve what they’re supposed to. Ultimately, it can slow down our progress toward energy efficiency goals and a more sustainable energy system. Overestimating savings can even lead to “greenwashing,” where organizations exaggerate their environmental performance, which damages their credibility and erodes public trust. On the flip side, underestimating savings can discourage further investment in energy efficiency, because the perceived benefits might not seem worth the costs.

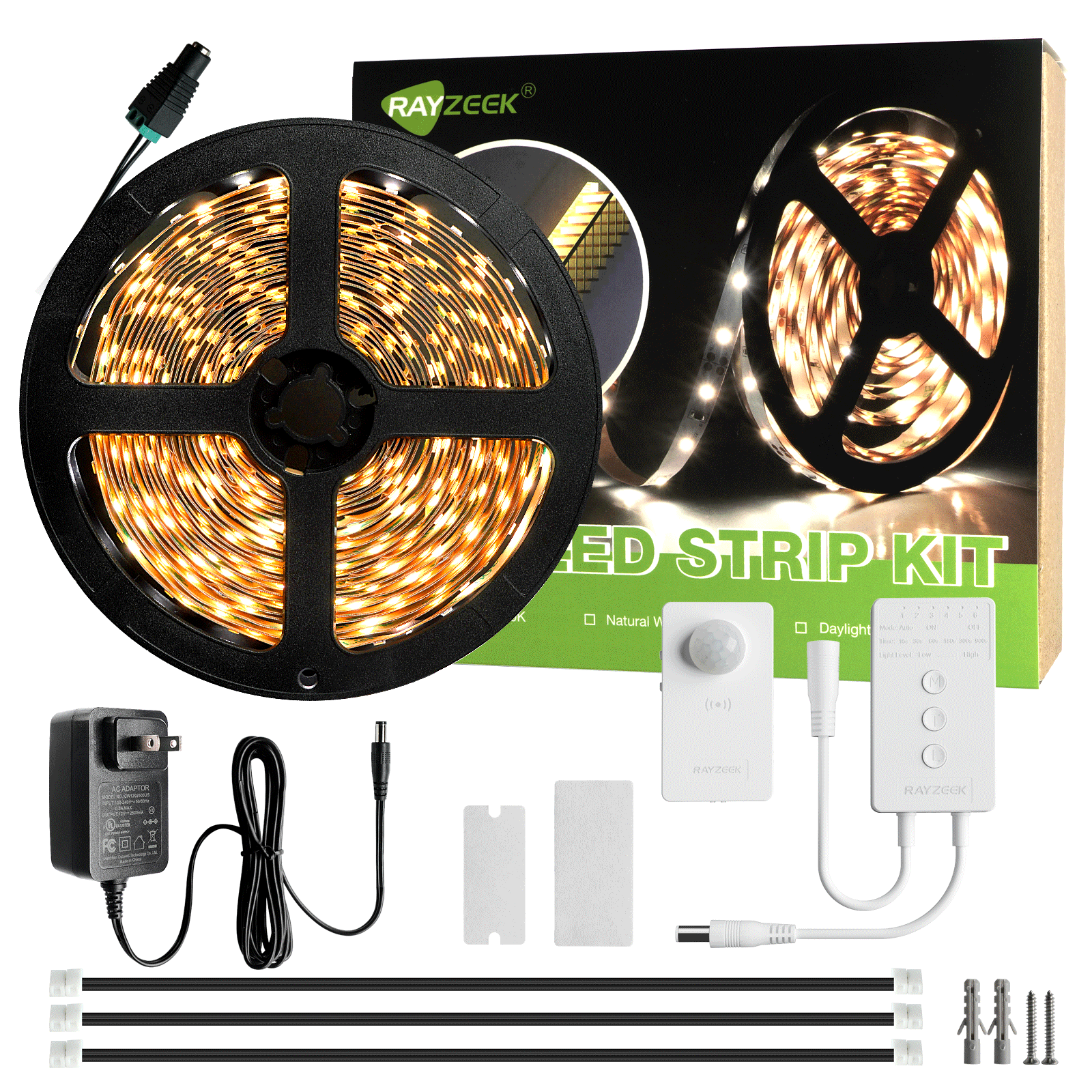

Looking For Motion-Activated Energy-Saving Solutions?

Contact us for complete PIR motion sensors, motion-activated energy-saving products, motion sensor switches, and Occupancy/Vacancy commercial solutions.

It’s important to realize that energy savings measurement can be applied in many different situations. We’re talking about everything from individual appliances to entire buildings, industrial processes, and even national energy consumption! While the basic principles of measurement stay the same no matter what you’re measuring, the complexity of the process can vary quite a bit depending on the scale and the systems involved. For example, measuring the energy savings of a single appliance is relatively simple. But measuring the savings of a complex industrial process or a whole country’s energy consumption? That requires much more sophisticated methods and data analysis.

Purpose of Measuring Energy Savings

One of the main reasons we measure energy savings is to figure out the financial benefits. The most obvious and immediate benefit for both individuals and organizations is lower energy costs. For instance, a homeowner who installs solar panels can see a significant drop in their monthly electricity bill. Similarly, a factory that implements energy-efficient machinery can reduce its operating expenses. But measuring energy savings is also crucial for calculating the Return on Investment (ROI) of energy efficiency investments. ROI helps us justify the initial costs and shows the long-term financial advantages of these investments. Several factors influence ROI, including the initial investment cost, the amount of energy savings, the price of energy, and how long the equipment or intervention lasts. It’s important to remember that while energy savings (measured in kilowatt-hours or British Thermal Units) might stay the same, the financial savings are directly linked to energy prices. If energy prices go up, the cost savings from a certain amount of energy savings will also increase. If prices go down, the cost savings will be lower. That’s why ROI calculations should ideally take into account potential price volatility and use projected energy prices over the lifespan of the energy-saving measure, rather than just relying on current prices. To get a more realistic picture of the potential financial benefits, you can use sensitivity analysis, which involves using a range of potential future energy prices.

Beyond the financial benefits, measuring energy savings is also crucial for understanding the environmental impact of energy efficiency measures. When we reduce energy consumption, we often reduce greenhouse gas emissions, which helps to mitigate climate change. This is especially true for energy sources that rely on fossil fuels, because burning these fuels releases greenhouse gases into the atmosphere. Energy efficiency is a key strategy for meeting international emissions reduction targets, like those outlined in the Paris Agreement, an international accord focused on combating climate change. Conserving energy also reduces our demand for natural resources like coal, oil, and natural gas, which helps to conserve those resources. And, because lower energy production can lead to reduced pollution, it can also improve environmental health by reducing the pollutants that power plants often release into the air and water.

You should also know that measuring energy savings is often required to comply with regulations. Many countries and regions have energy efficiency standards that require energy savings measurement and reporting. These standards can take various forms, such as building codes that set minimum energy performance levels for new buildings, appliance efficiency standards that limit the energy consumption of appliances, and industrial energy efficiency targets that require industries to reduce their energy intensity (the amount of energy used per unit of production). If you don’t comply with these regulations, you could face penalties, fines, and damage to your reputation. On the other hand, governments and utilities often offer incentives, like rebates and tax credits, for making energy efficiency improvements. To get these incentives, you’ll typically need to measure your energy savings to prove that you’ve actually achieved them. This verification process ensures that public funds are used effectively and that the intended energy savings are realized, preventing fraud and misuse of incentives.

Finally, measuring energy savings gives you objective data that you can use to make informed decisions. This data allows you to evaluate how well different energy-saving strategies are working, compare their performance, and identify the interventions that have the biggest impact. It also helps you spot areas where you can make further improvements, pinpointing specific processes or equipment that are using more energy than they should be. This makes it easier to continuously improve your energy performance, allowing organizations and individuals to progressively reduce their energy consumption over time.

It’s interesting to see how different countries approach the promotion and regulation of energy savings measurement and verification (M&V). Some, like the European Union, have implemented mandatory energy audits for large companies and strict building energy codes, creating a strong regulatory framework. Mandatory energy audits are systematic inspections of a building’s energy use to identify areas for improvement. Other countries, like the United States, tend to rely more on voluntary programs and tax incentives, encouraging energy efficiency through market-based mechanisms. These mechanisms use financial incentives to encourage energy efficiency. By comparing the effectiveness of these different approaches, we can gain valuable insights into the best practices for developing effective energy policies. For example, countries with stronger M&V requirements often see higher levels of compliance and greater overall energy savings, which suggests that strong regulations can be an effective way to drive energy efficiency.

Measurement and Verification (M&V)

Let’s talk about Measurement and Verification, or M&V. M&V is a systematic process for reliably figuring out how much energy you’re saving. It’s not just about taking a few measurements here and there. It’s about following a structured approach to make sure that the savings you report are accurate and credible. Why do we need a standardized process? Because it ensures consistency, comparability, and transparency in energy savings reporting. Consistency means that measurements are taken in the same way across different projects and time periods. Comparability allows you to make meaningful comparisons between different projects or interventions. And transparency means that the methods and data you use are clearly documented and accessible for review.

The M&V process is built on several key principles:

- Accuracy: This means minimizing errors in your measurements and calculations. To achieve accuracy, you need to use properly calibrated instruments (instruments that have been checked and adjusted to ensure they’re measuring correctly) and validated data (data that has been checked for accuracy and reliability) to ensure that your measurements are as close as possible to the true values.

- Completeness: You need to account for all relevant energy flows and factors that influence energy consumption. For example, if you’re measuring the savings from a new lighting system, you have to consider all the lights that are affected, not just a sample. If you leave some lights out of the calculation, you’ll end up with an incomplete and inaccurate assessment.

- Conservativeness: It’s important to avoid overestimating your savings. It’s better to slightly underestimate them than to inflate them, because that ensures a realistic and credible assessment.

- Consistency: Use the same methods and procedures over time. This ensures that comparisons between different periods (like before and after an intervention) are valid and not influenced by changes in your measurement techniques.

- Transparency: Clearly document the methods, assumptions, and data that you use. This allows others to understand and verify your results, which promotes accountability and trust.

- Relevance: Measure the energy savings that are directly attributable to the intervention. This helps you avoid claiming savings that are due to other factors, like changes in the weather or how many people are occupying a building.

Let’s dive into the International Performance Measurement and Verification Protocol, or IPMVP. This is the most widely recognized standard for M&V, providing a framework and guidelines for developing and implementing M&V plans. Think of it as a roadmap for ensuring a consistent and rigorous approach to measuring energy savings. The IPMVP offers different “options” for M&V, giving you flexibility depending on your specific project and the level of accuracy you need.

M&V Options (within IPMVP)

Okay, let’s take a look at the different M&V options available within the IPMVP framework:

- Option A: Retrofit Isolation – Key Parameter Measurement. This option focuses on measuring the key performance parameters of the energy conservation measure, or ECM. An ECM is essentially any action you take to save energy. For example, if you’re installing a more efficient chiller in a chilled water system (a system that cools water for air conditioning), you’d measure the flow rate and temperature difference of the water before and after the installation. These are the key parameters that determine how well the chiller is performing. Option A is a good choice when the ECM’s performance can be reliably determined by a few key parameters that are relatively easy to measure. It’s often used for simpler retrofits, where a “retrofit” is an upgrade or modification to an existing system, and where the impact of the ECM is well-defined.

- Option B: Retrofit Isolation – All Parameter Measurement. This option takes a more comprehensive approach, measuring all the relevant parameters that affect the energy use of the system impacted by the ECM. For instance, if you’re installing a variable frequency drive, or VFD, on a motor (a VFD is a device that controls the speed of a motor), you’d measure the motor’s power consumption, operating hours, and load before and after the installation. All of these parameters influence how much energy the motor uses. Option B is suitable when you need a more complete picture of the ECM’s impact, requiring you to measure all the relevant parameters. This is often used for more complex retrofits or when there are potential interactions between the ECM and other systems.

- Option C: Whole Facility. This option uses utility meter data – the data from your electricity, gas, or other energy meters – to compare energy consumption before and after you implement multiple ECMs. For example, you might analyze your monthly electricity bills for a building before and after implementing a range of energy efficiency upgrades, such as improvements to the lighting, HVAC (heating, ventilation, and air conditioning), and insulation. Option C is a good choice when it’s difficult or impractical to isolate the impact of individual ECMs. This is often the case when you’ve implemented multiple ECMs at the same time, or when the ECMs affect the entire facility’s energy consumption in a complex way.

- Option D: Calibrated Simulation. This option uses computer simulation models to predict energy consumption before and after you implement ECMs. For example, you might use building energy modeling software to simulate the energy performance of a building with and without proposed energy efficiency improvements. The software takes into account factors like the building’s design, how many people occupy it, the weather, and the performance of its equipment. Option D is suitable when it’s difficult or impossible to take actual measurements, such as when you’re predicting the energy savings of a new building design before it’s even built, or when the ECM involves complex interactions that are best modeled through simulation. This option relies on creating a calibrated computer model of the building or system. “Calibration” means adjusting the model’s parameters until it accurately reflects the actual energy consumption of the existing building or system, using historical data. Once the model is calibrated, you can use it to simulate the impact of the ECM.

So, how do you choose the right M&V option? Well, it depends on several factors, including the complexity of your project, your budget, the level of accuracy you need, and the data that’s available. More complex projects often require more sophisticated options, like Option B or D, while simpler projects can get away with using Option A. Your budget also plays a role, since some options are more expensive to implement than others. And, of course, the level of accuracy you need will influence your choice, with higher accuracy generally requiring more detailed measurements.

Now, let’s talk about the M&V Plan. This is a crucial document in the energy savings measurement process. It’s a document that outlines the specific procedures, methods, and data analysis techniques you’ll use to measure and verify energy savings for a particular project. Think of it as a roadmap for the entire M&V process, ensuring that everything is done consistently and transparently.

What are the key components of an M&V plan? Here are some of the most important things to include:

- Project description and objectives: A clear statement of what you’re trying to achieve with the project and the specific energy savings you expect to see.

- Identification of the energy-saving measures: A detailed description of the specific actions or interventions you’ve implemented to reduce energy consumption.

- Baseline period and data: A definition of the period before you implemented the energy-saving measures that you’ll use as your baseline, and a specification of the data you’ll collect to establish that baseline. This includes the types of data you’ll collect (e.g., energy consumption, operating hours) and the sources of that data (e.g., utility bills, submeters). Submeters are meters installed to measure the energy consumption of specific equipment or areas within a facility, giving you more granular data than you’d get from your utility bills alone.

- Post-implementation period and data collection procedures: A definition of the period after you implemented the energy-saving measures, and a specification of the data collection procedures you’ll use to measure energy consumption during that period. These procedures should be consistent with the ones you used for the baseline period.

- Calculation methodology: A specification of the equations and methods you’ll use to calculate energy savings, based on the baseline and post-implementation data.

- Uncertainty analysis: An assessment of the potential errors and uncertainties in your measurements and calculations, and a quantification of the overall uncertainty in the reported energy savings.

- Reporting procedures: A description of how you’ll report your energy savings, including the format and frequency of your reports.

Fundamentals of Measurement

Baseline Energy Consumption

Let’s talk about baseline energy consumption. This is the energy consumption before you implement any energy-saving measures. It serves as the reference point against which you’ll compare your post-implementation energy consumption. In other words, it’s what you’ll use to figure out how much energy you’ve saved. This baseline is used in the fundamental calculation of energy savings, which is simply the difference between your baseline energy use and your post-implementation energy use. Without a reliable baseline, it’s impossible to accurately determine how much energy you’ve saved. Any apparent reduction in energy consumption could be due to factors that have nothing to do with your energy-saving measures.

Maybe You Are Interested In

Establishing a Baseline

So, how do you go about establishing a reliable baseline? Well, it involves several key steps, including data collection, potentially conducting energy audits, and making adjustments to the baseline to account for changing conditions.

The first step is data collection. This involves gathering historical energy consumption data for the facility, system, or equipment you’re interested in. This historical data provides a record of your energy use patterns before you made any changes, which allows you to compare it with your post-implementation data.

Where can you get the data you need to establish a baseline? Here are some common sources:

- Utility bills: Your monthly or bimonthly bills from your electricity, gas, or other energy providers. These bills provide a record of your overall energy consumption.

- Submeters: As we mentioned earlier, submeters are meters installed to measure the energy consumption of specific equipment or areas within a facility. They provide more granular data than your utility bills.

- Building Management Systems (BMS): These are computer-based systems that monitor and control building systems, often including energy consumption data for various equipment and systems.

- Energy Audits: Data collected during professional energy audits, which may include detailed measurements of energy use patterns.

- Manual readings of meters: Readings you take directly from meters, particularly for equipment that isn’t connected to a BMS or submetered.

What types of data do you need to establish a comprehensive baseline? Here are some of the most important:

- Energy consumption (kWh, BTU, etc.): The actual amount of energy you consumed over a specific period, such as hourly, daily, or monthly.

- Operating hours: The number of hours that your equipment or system was in operation during the measurement period.

- Production levels: For industrial facilities, the quantity of goods produced during the measurement period. This is important for normalizing energy consumption to production output. Normalizing energy consumption means adjusting it to account for changes in production levels, so you can compare energy use across different periods even if your production output has changed.

- Occupancy data: For buildings, the number of occupants or the occupancy rate during the measurement period. Occupancy levels can significantly affect energy consumption.

- Weather data: Outdoor temperature, humidity, and solar radiation data, as these factors can influence heating and cooling loads.

To get a good picture of how your energy consumption varies throughout the year, it’s generally recommended that you collect data for at least one year. A full year of data accounts for changes in heating and cooling needs during the different seasons, giving you a more representative baseline. In some cases, you might want to collect data for even longer – say, two or three years – to account for year-to-year variations in weather or other factors.

If you’re a homeowner, you can use a simplified approach to establishing a baseline, although it won’t be as precise as the methods used by professionals. This involves gathering 12-24 months of utility bills (both electricity and gas, if applicable). Then, record the energy usage (kWh for electricity, therms or BTU for gas) for each month. Also, make sure to note any significant changes in occupancy, such as family members moving in or out, or major appliance purchases, such as a new refrigerator or air conditioner, during that time. While this approach isn’t as precise as professional methods, it can give you a rough but useful baseline for comparing your energy consumption and understanding your personal energy use patterns.

Another important tool for establishing a baseline is energy audits. Energy audits are professional assessments of energy use patterns within a facility or building. They help you identify potential energy-saving opportunities and can provide valuable data for establishing a baseline. In fact, audits can help you identify the factors that influence your energy consumption, such as inefficient equipment, poor insulation, or operational practices. By giving you a detailed understanding of your energy use, audits can inform your baseline development.

Get Inspired by Rayzeek Motion Sensor Portfolios.

Doesn't find what you want? Don't worry. There are always alternate ways to solve your problems. Maybe one of our portfolios can help.

Energy audits typically come in different levels, depending on how deep the analysis goes:

- Walk-through audits (Level 1): This is a preliminary assessment that involves a visual inspection of the facility and a review of utility bills. It gives you a basic understanding of your energy use and helps you identify potential areas for improvement.

- Detailed audits (Level 2): This is a more comprehensive assessment that includes detailed data collection, analysis of energy consumption patterns, and identification of specific energy-saving measures, along with cost estimates and payback periods.

- Investment-grade audits (Level 3): This is the most rigorous type of audit, providing detailed engineering analysis and financial modeling to support investment decisions in major energy efficiency projects.

Finally, you might need to make adjustments to your baseline to account for factors that changed between the baseline period and the post-implementation period. These adjustments ensure that you’re making a fair and accurate comparison between your baseline and post-implementation energy consumption, allowing you to isolate the impact of your energy-saving measures.

What kind of factors might require you to adjust your baseline? Here are a few examples:

- Changes in occupancy: If the number of people using a building increases or decreases, it can significantly affect energy consumption.

- Changes in production levels: In industrial facilities, changes in the quantity of goods produced can affect energy use.

- Changes in weather conditions: If the weather is unusually hot or cold during the post-implementation period compared to the baseline period, it can affect heating and cooling loads.

- Changes in Operating Hours: If a building or piece of equipment operates for significantly different hours after the energy efficiency measure is implemented.

Making these adjustments is crucial for ensuring a fair and accurate comparison between your baseline and post-implementation energy consumption. Without them, changes in external factors could be mistaken for energy savings (or a lack thereof) due to your energy efficiency measures. Remember, the goal is to isolate the impact of the energy-saving measures themselves, and adjustments help you do that by accounting for other factors that might be influencing your energy consumption.